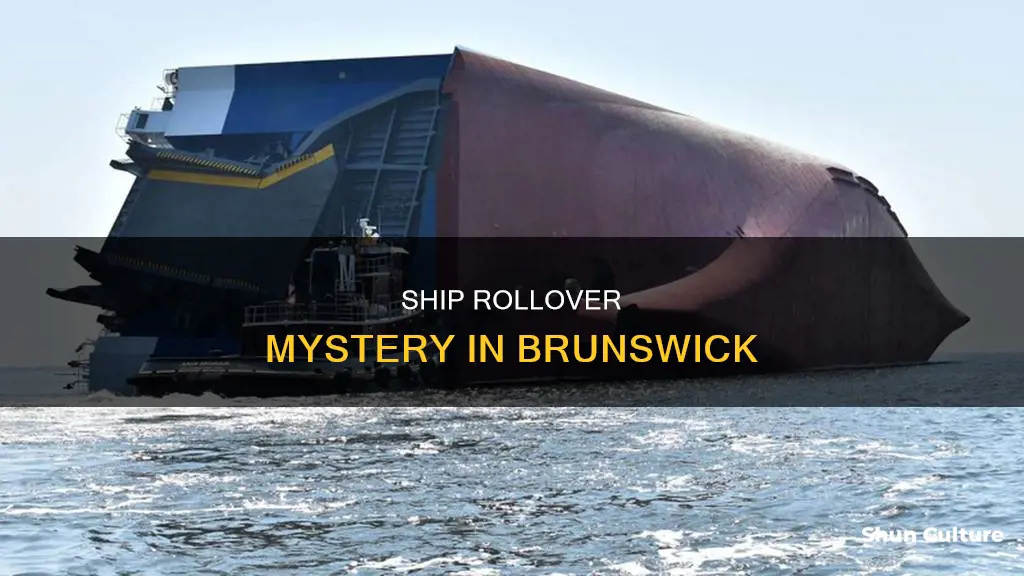

On 8 September 2019, the MV Golden Ray cargo ship capsized in St. Simons Sound near the Port of Brunswick in Georgia, United States. The 656-foot ship was carrying 4,100 vehicles when it overturned, resulting in more than $200 million in damage. All 24 crew members were rescued alive, although four were trapped inside the engine compartment for over 30 hours. The cause of the incident was initially unknown, but investigations revealed that it was due to a combination of incorrect ballast entries, open watertight doors, and incorrect cargo stowage, which affected the ship's stability.

| Characteristics | Values |

|---|---|

| Date of incident | 8 September 2019 |

| Time of incident | 01:37 EDT |

| Location | St. Simons Sound near the Port of Brunswick in Georgia, United States |

| Ship name | MV Golden Ray |

| Ship type | Roll-on/roll-off cargo ship |

| Cargo | Approximately 4,300 brand new cars |

| Cause of capsizing | Incorrect stability calculations, open watertight doors, incorrect ballast entries |

| Response teams | US Coast Guard, Glynn County first responders |

| Evacuation status | All 23 crew members and 1 pilot evacuated safely |

What You'll Learn

The cargo ship's stability calculations were incorrect

Stability calculations for cargo ships are complex and focus on centres of gravity, centres of buoyancy, and metacentre—how these interact determines a ship's stability. Incorrect calculations can lead to a loss of stability and even capsizing.

The cargo ship MV Golden Ray capsized in St. Simons Sound near the Port of Brunswick, Georgia, on September 8, 2019. The National Transportation Safety Board (NTSB) determined that the direct cause of the capsizing was incorrect entries for ballast in the ship's stability calculation program. The program did not compute the proper levels for ballast tanks, which left the ship unstable as it made a sharp turn when exiting the channel.

The NTSB report also noted that there was no procedure to verify the entries, which compounded the issue. When the ship heeled to port, the open portside pilot door allowed water to enter, and the ship began to list. Other watertight doors that were not properly closed also allowed flooding.

The incorrect stability calculations, combined with the improper closure of watertight doors, led to the capsizing of the Golden Ray and resulted in more than $200 million in damage.

Brunswick's Memorial Day Parade

You may want to see also

Two watertight doors were left open

The capsizing of the Golden Ray cargo ship in September 2019 was caused by a combination of factors, including incorrect stability calculations and two open watertight doors. The National Transportation Safety Board (NTSB) determined that the direct cause of the capsizing was incorrect entries for ballast in the ship's stability calculation program. This error went unnoticed due to the absence of a verification procedure. As a result, the program failed to compute the appropriate levels for ballast tanks, leaving the ship unstable as it made a sharp turn when exiting the channel.

Watertight doors are a critical safety feature on ships, designed to prevent the ingress of water between compartments during flooding or accidents. They are typically located in areas with a high risk of flooding, such as engine rooms and shaft tunnels. The proper use and maintenance of these doors are essential for preserving the stability and buoyancy of the vessel. There are different types of watertight doors, each with specific operating criteria. Type A doors, for example, can be left open and are closed only in emergencies. Type B doors should remain open only when personnel are working in adjacent compartments. Type C doors, on the other hand, must be kept closed at all times, except when personnel need to pass through. Lastly, Type D doors are not SOLAS (Safety of Life at Sea) compliant and must be closed throughout the voyage.

In the case of the Golden Ray, two of these watertight doors were left open, which contributed to the flooding of the vessel after it capsized. The NTSB report revealed that the ship's instability caused it to heel rapidly to its port side. The open portside pilot door, along with other improperly closed watertight doors, allowed water to enter the ship, leading to flooding in the engine and steering gear rooms. This flooding trapped four crew members who were later rescued.

The incident underscores the critical importance of proper watertight door management and maintenance. It is imperative that crew members are familiar with the operation and safety precautions associated with these doors. Regular drills and inspections are necessary to ensure the doors' functionality and crew preparedness. The consequences of neglecting watertight door integrity can be disastrous, as evident in the case of the Golden Ray and other maritime incidents.

May Eddings: Ohio's Centenarian

You may want to see also

The ship's ballast tanks were incorrectly filled

The capsizing of the MV Golden Ray cargo ship in St. Simons Sound near Brunswick, Georgia, in September 2019, was a result of several factors, one of which was the incorrect filling of ballast tanks.

Ballast tanks are integral to maintaining the stability of a ship during its voyage. The ballast operation helps compensate for weight loss as the ship continually uses fuel and water, ensuring the propeller remains immersed for efficient engine performance. Additionally, ballast helps improve manoeuvrability by keeping the rudder immersed and reducing the exposed hull surface.

In the case of the Golden Ray, the chief officer transferred water from the no. 5 port water ballast tank to the no. 5 starboard water ballast tank shortly after leaving the Port of Brunswick. This action corrected a list from 0.42° to port to 0.03° to starboard. However, when the ship began to turn and heel to port rapidly, the incorrect ballast distribution may have contributed to the instability.

The National Transportation Safety Board (NTSB) determined that the direct cause of the capsizing was incorrect entries for ballast in the ship's stability calculation program. The program's error, combined with the absence of a verification procedure, resulted in improper ballast tank levels, leaving the ship unstable as it made a sharp turn when exiting the channel.

To prevent such incidents, it is crucial to ensure accurate calculations and proper procedures for ballast management. The Chief Officer and Master of the ship are responsible for adding or removing ballast water, following the specifications in the ship's loading manual and adhering to port ballast restrictions.

Tysons to New Brunswick: Road Trip

You may want to see also

The ship's cargo was loaded incorrectly

On September 8, 2019, the MV Golden Ray cargo ship capsized in St. Simons Sound near the Port of Brunswick in Georgia, United States. The ship was carrying approximately 4,300 brand new cars manufactured by Kia, Hyundai, Chevrolet, GMC, GM, Mercedes-Benz, and Ram.

The National Transportation Safety Board (NTSB) determined that the direct cause of the capsizing was incorrect entries for ballast in the ship's stability calculation program. There was no procedure to verify the entries, which meant that the program did not compute the proper levels for ballast tanks, leaving the ship unstable as it made a sharp turn when exiting the channel.

While the incorrect ballast entries were the direct cause of the capsizing, the NTSB also found that two watertight doors had been left open, which caused the vessel to flood after it capsized. This flooding trapped four crew members who were later rescued.

The cargo ship's stability calculations were incorrect due to a combination of factors, including improper loading of cargo and incorrect water ballasting. The incorrect entries for ballast in the stability calculation program were a result of human error and the lack of a verification procedure.

To prevent container rollover, it is important to ensure that all containers are properly loaded and secured to the ship. This includes checking that the cargo inside the container is properly secured and that the container is properly balanced. In addition, it is crucial to maintain and regularly inspect the ship's equipment to ensure that it is in good working order, as a malfunction can easily cause container rollover.

Princeton Guide: Accessing NJTV from New Brunswick

You may want to see also

The ship's centre of gravity was too high

The capsizing of the MV Golden Ray in September 2019 was a result of multiple factors, one of which was the ship's centre of gravity being too high.

The Golden Ray was a roll-on/roll-off cargo ship designed to carry automobiles. On its final voyage, it was loaded with approximately 4,300 brand new cars. The ship stopped at various ports, including Veracruz, Altamira, Freeport, Jacksonville, and Brunswick, where vehicles were unloaded and loaded.

The centre of gravity of a ship is crucial to its stability, and an incorrect assessment of the ship's stability can lead to capsizing. In the case of the Golden Ray, the replacement of hundreds of subcompact cars with heavier Kia Telluride SUVs raised the ship's centre of gravity. This change in cargo weight distribution altered the ship's balance and contributed to its instability.

The ship's high centre of gravity, combined with other factors such as incorrect ballast calculations and open watertight doors, led to the capsizing. The weight distribution and stability calculations are essential factors in ensuring the safety of cargo ships, and even a small miscalculation can have significant consequences, as evidenced by the Golden Ray incident.

The investigation into the Golden Ray's capsizing revealed a complex interplay of factors, including the ship's design, cargo loading, ballast management, and human factors. This incident serves as a stark reminder of the importance of accurate stability calculations, proper cargo loading procedures, and maintaining a low centre of gravity to prevent similar incidents in the future.

Grandparents' Rights in New Brunswick

You may want to see also

Frequently asked questions

The direct cause of the capsizing of the MV Golden Ray was incorrect entries for ballast in the ship's stability calculation program. The program entry error was compounded by the absence of a procedure to verify the entries. The incorrect entries meant the program did not compute the proper levels for ballast tanks, which left the ship unstable as she made a sharp turn when exiting the channel.

The list reached 60° within a minute and at 01:40 EDT, the ship ran aground. All 23 crew members and the pilot survived, although the rescue of four crew members trapped in the stern took over 30 hours.

The incident resulted in more than $200 million in damage. The ship was declared a total loss, estimated at $62.5 million, and there was an estimated $142 million worth of cargo lost. The US Coast Guard called the wreck "unprecedented" and it took over 3 million collective man-hours to remove the ship, making it the largest wreck removal operation in US history.

A fire broke out on the starboard side of the ship, consuming the vehicles inside and releasing toxic smoke and heat. This prevented further rescue operations for approximately 24 hours until the fire had burned out.