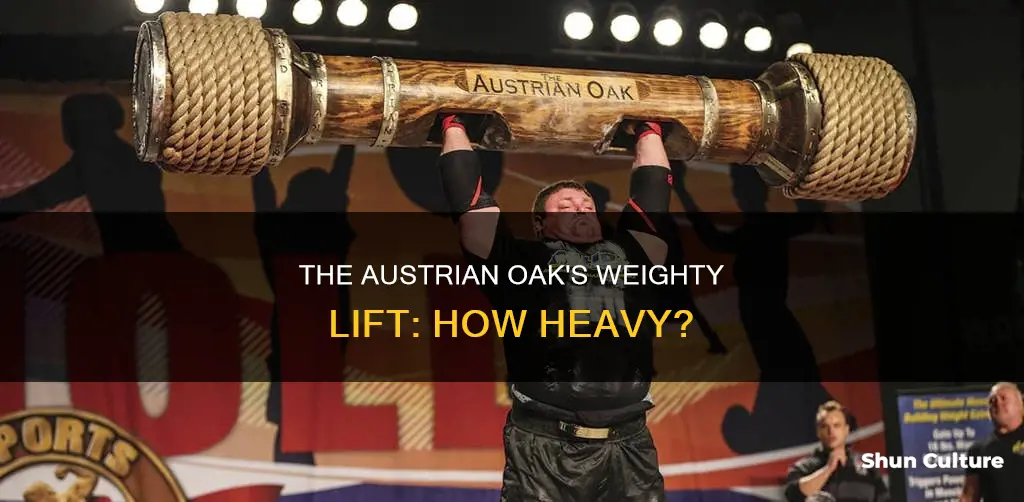

The Austrian Oak is a log of mammoth proportions, crafted entirely of wood and weighing in at 440-460+ lbs. Introduced in 2012 at the Arnold Strongman Classic, it is one of the most interesting lifting events in the modern era. Competitors are tasked with lifting the oak from the ground and pressing it overhead. For those unable to press the Austrian Oak, there is a lighter variant weighing around 375 lbs.

| Characteristics | Values |

|---|---|

| Weight | Typically 440-460+ lbs, but varies year to year |

| Length | Very long |

| Material | Wood |

| Introduced | 2012 |

| Introduced by | Steve Slater |

What You'll Learn

- The Austrian Oak is a log of mammoth proportions, built by Steve Slater

- It is made entirely of wood, so its weight varies year to year

- The log typically weighs in excess of 460 lbs

- Competitors are tasked with lifting the log from the ground and pressing it overhead

- In 2015, Žydrūnas Savickas pressed the oak four times, despite it weighing 503 lbs

The Austrian Oak is a log of mammoth proportions, built by Steve Slater

The Austrian Oak is one of the most interesting lifting events in the modern era. Competitors are not only tasked with lifting this monstrosity from the ground, but they must attempt to press it overhead. For those that cannot press the Austrian Oak, they get a chance at the feather log, which weighs in at a 'light' 375 lbs.

Jerry Pritchett’s pressing strength keeps climbing with this 415lb lift put in training but the Oak is still a bit far off. Expect Pritchett to put up 5-6 reps on the feather log. Mateusz Kieliszkowksi, the 21-year-old Polish Strongman, shocked the world last year taking third overall. The very explosive athlete is probably not up to the challenge of the Austrian Oak yet but I expect him to have the most reps of anyone on the feather log.

Eurail Global Pass: Exploring Austria and Beyond

You may want to see also

It is made entirely of wood, so its weight varies year to year

The Austrian Oak is a log of mammoth proportions, made entirely of wood. It was introduced in 2012 at the Arnold Strongman Classic and is considered one of the most interesting lifting events in the modern era. The oak varies in weight yearly, but can typically reach an excess of 460+ lbs. In 2015, Žydrūnas Savickas pressed the oak four times, which weighed 503 lbs that year.

The oak is a true test of strength for competitors, who are tasked with lifting it from the ground and pressing it overhead. The sheer length and size of the log make it much more challenging than an equal-weight steel gym log. For those who are unable to press the Austrian Oak, there is a "lighter" variant weighing around 375 lbs, known as the feather log.

The oak's weight can vary due to a variety of factors, including the moisture content of the wood and the specific type of wood used. Over time, the wood may also expand or contract slightly, affecting its weight. Additionally, the oak is exposed to varying environmental conditions, such as temperature and humidity, which can impact its weight.

The Austrian Oak is a testament to the craftsmanship of its builder, Steve Slater, who has created a beautiful and challenging piece of Strongman equipment. Its varying weight adds an element of unpredictability to the competition, making it a true test of strength and skill for athletes.

Austria's Chances Against Italy: A Footballing Upset?

You may want to see also

The log typically weighs in excess of 460 lbs

The Austrian Oak is a log of mammoth proportions, beautifully crafted entirely of wood. It was introduced in 2012 at the Arnold Strongman Classic and is considered one of the most interesting lifting events in the modern era. The log typically weighs in excess of 460 lbs, but its weight varies from year to year. In 2015, it weighed 503 lbs, and Žydrūnas Savickas pressed it overhead not once, but a total of four times.

The Austrian Oak is a true test of strength and endurance for competitors. The sheer length and size of the log make it much more challenging than an equal-weight steel gym log. Competitors are not only tasked with lifting the log from the ground, but they must also attempt to press it overhead. This requires a tremendous amount of strength and technique.

In the years since its introduction, the Austrian Oak has become a highly anticipated event at the Arnold Classic. Athletes from around the world compete to see who can lift and press the heaviest weight. It is a true showcase of human strength and determination.

While the Austrian Oak typically weighs over 460 lbs, there is a "lighter" variant weighing around 375 lbs for competitors who are unable to press the heavier log. This variant is known as the "feather log". Despite its lighter weight, the feather log still presents a significant challenge for competitors, requiring multiple reps to demonstrate their strength.

Austria-Hungary's WWI Advances: Technology and Tactics

You may want to see also

Competitors are tasked with lifting the log from the ground and pressing it overhead

The Austrian Oak is a log of mammoth proportions, beautifully crafted entirely of wood. It was introduced in 2012 at the Arnold Strongman Classic and is among one of the most interesting lifting events in the modern era. The weight of the log varies yearly, but it can typically reach an excess of 460 lbs.

Jerry Pritchett’s pressing strength keeps climbing with this 415lb lift put in training, but the Oak is still a bit far off. Expect Pritchett to put up 5-6 reps on the feather log. Mateusz Kieliszkowksi, the 21-year-old Polish Strongman, shocked the world last year taking third overall. The very explosive athlete is probably not up to the challenge of the Austrian Oak yet, but he is expected to have the most reps of anyone on the feather log.

Krakow's Historical Ties with Austria: A Complex Past

You may want to see also

In 2015, Žydrūnas Savickas pressed the oak four times, despite it weighing 503 lbs

The Austrian Oak is a log of mammoth proportions, crafted entirely of wood, and introduced at the Arnold Strongman Classic in 2012. It is considered one of the most interesting lifting events in the modern era. The oak varies in weight yearly, but can typically reach an excess of 460 lbs.

Competitors at the Arnold Strongman Classic are tasked with lifting the oak from the ground and pressing it overhead. Those unable to press the oak are given a "lighter" variant weighing around 375 lbs, known as the feather log. In 2014, Lalas was able to press the oak successfully, but it is unclear if he was able to do so in 2015. Jerry Pritchett, for example, had been training with a 415lb lift, but the oak was still a bit far off.

Savickas' achievement in pressing the oak four times despite its heavy weight showcases his incredible strength and endurance. It is a testament to his dedication and training, solidifying his place as one of the strongest men in the world.

Romania's Attack on Austria-Hungary: Why and When?

You may want to see also

Frequently asked questions

The Austrian Oak is a wooden log, so its weight varies year to year. It typically weighs around 440-460+ lbs, but can sometimes exceed 500 lbs.

The Austrian Oak is so heavy that most competitors can't lift it at all. Those who can manage it usually do 4-6 reps.

The feather log is a lighter version of the Austrian Oak, weighing around 375 lbs. Competitors who can't lift the Austrian Oak are given a chance to lift this instead.

Lithuanian athlete Žydrūnas Savickas has lifted the Austrian Oak, as has Lalas.