Brunswick bowling balls are made of rubber. The company introduced rubber bowling balls in 1906, with the launch of its Mineralite ball, which cost $20 and boosted the popularity of the sport.

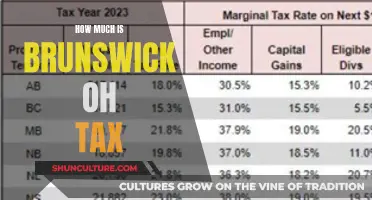

| Characteristics | Values |

|---|---|

| Composition | Non-hazardous materials, including rubber |

| Manufacturing location | Muskegon, Michigan |

What You'll Learn

Brunswick bowling balls are made of non-hazardous materials

The materials used to craft Brunswick bowling balls are safe and non-toxic, ensuring that players can enjoy their game without worrying about any potential health risks. This commitment to safety is a testament to Brunswick's dedication to creating a positive and healthy bowling experience for all enthusiasts.

In addition to using non-hazardous materials, Brunswick has also been at the forefront of standardising the rules of bowling and establishing professional tournaments. The company played a pivotal role in the birth of the sport by taking it out of fancy Victorian parlours and into the public arena. This demonstrates Brunswick's passion for making bowling accessible and enjoyable for everyone.

The history of Brunswick bowling balls dates back to the company's early years. Moses Bensinger, son-in-law of founder John Moses Brunswick, recognised the potential of the then-disorganised sport. He began crafting wooden lanes, pins, and bowling balls, setting the standard for the modern game.

Brunswick's commitment to safety extends beyond the materials used in their bowling balls. The company has always prioritised the well-being of its customers and players, ensuring that their products meet high standards of quality and safety. This dedication to safety is a key aspect of Brunswick's brand and reputation.

The non-hazardous nature of Brunswick bowling balls is just one example of the company's commitment to its customers. By using safe and non-toxic materials, Brunswick ensures that players can focus on their game and improve their skills without worrying about potential health risks associated with the equipment.

In conclusion, Brunswick bowling balls are crafted with the utmost care and attention to safety. The company's use of non-hazardous materials is a testament to their dedication to creating a positive and healthy bowling experience for enthusiasts around the world. With a rich history in the sport, Brunswick continues to innovate and prioritise the well-being of its customers.

St. Peters Offers New Brunswick In-Hospital Learning

You may want to see also

The company was founded in 1845 by John Brunswick

John Brunswick founded the company in 1845 after emigrating to the United States from Switzerland's Rhine Valley. A master carriage-maker and woodworker by trade, he opened a shop in Cincinnati, Ohio, where he was introduced to billiards and began crafting billiards tables. His company, originally called the Cincinnati Carriage Making Company, soon expanded its product line beyond carriages to include cabinets, tables, and chairs.

The company's first billiards table was produced in 1845 for a successful Cincinnati meatpacker. Word-of-mouth promotion quickly brought requests for more tables, and the company boasted, "If it is wood, we can make it, and we can make it better than anyone else can." This early success laid the foundation for what would become the Brunswick Corporation.

John Brunswick's two brothers joined the business, and the company was renamed J.M. Brunswick and Brothers Billiard Table Manufacturing. However, John's brothers would eventually leave the firm to start rival firms and billiard parlours in Chicago and San Francisco.

Despite this competition, John Brunswick's company continued to thrive, and he merged with rival Julius Balke's Great Western Billiards Table Manufactory to become The J. M. Brunswick and Balke Company. He later merged with another competitor, New York-based Phelan & Collender, forming the Brunswick-Balke-Collender Company, which became the largest billiards equipment operation in the world, dominating the US billiards market.

Under John Brunswick's leadership, the company continued to innovate and expand its product offerings. It entered the bowling business in the 1880s, producing wooden lanes, bowling pins, and bowling balls. This expansion into the bowling industry solidified the company's presence in the world of recreational sports and set the stage for its future growth and success.

New Brunswick Police: Armed and Ready?

You may want to see also

Brunswick bowling balls were first made in Michigan

In 1903, the company headquarters relocated to western Michigan, specifically Muskegon, to capitalise on the region's lumber trade. This move paved the way for Brunswick's entry into the bowling business, as Moses Bensinger, son-in-law of John Brunswick, saw the potential in the then-disorganised sport. He began making wooden lanes, pins, and bowling balls, playing a pivotal role in establishing the American Bowling Congress in 1895.

The company's presence in Muskegon led to the area becoming a hub for bowling manufacturing. The iconic Muskegon plant produced bowling balls, pins, and equipment for a century, with its peak employing around 3,000 people and operating 11 factories in the town. The company's impact extended beyond the bowling industry, as it provided housing for employees, known as Brunswick Row, and even influenced the city's landmarks and directions.

However, in the early 2000s, Brunswick started moving its production lines overseas, and in 2006, the Muskegon plant was shut down, with production shifted to Mexico. Despite this shift, Brunswick bowling balls remain an integral part of the company's history and Michigan's industrial past, with the balls themselves made from non-hazardous materials.

Prostitution in New Brunswick: What's the Law?

You may want to see also

The company moved its bowling ball production to Mexico

Brunswick Corporation, the world's largest maker of bowling equipment, announced in 2005 that it would move its bowling ball production from Muskegon, Michigan, to a plant in Reynosa, Mexico. The company cited high labor costs as the reason for the move, stating that it would save between $5 million and $6 million annually by relocating its manufacturing operations. This decision resulted in the loss of approximately 115 jobs in Muskegon, where the company had maintained its sole production line since 1906.

The move to Mexico was part of Brunswick's efforts to reduce costs and improve efficiency by consolidating manufacturing operations. In addition to bowling balls, the company produced a range of other products, including bowling pins, toilet seats, truck tires, and bowling alley equipment. Over time, Brunswick expanded its global presence, establishing manufacturing plants and sales offices in various countries, including Hungary, Mexico, and China.

The decision to move bowling ball production to Mexico was not unexpected, as the company had been negotiating with its unionized workers for some time. While it was an emotional loss for the community, it was primarily a symbolic one, as Muskegon had been adding manufacturing jobs in recent years, and Brunswick continued to maintain a presence in the area with white-collar jobs in sales and support.

The move to Mexico was part of Brunswick's long history of adapting to changing economic conditions and market demands. Founded in 1845 by John Brunswick, a master woodworker and carriage-maker, the company initially produced carriages, tables, and chairs. Over the years, it expanded into billiards and bowling, with Moses Bensinger, John Brunswick's son-in-law, playing a pivotal role in the development of the bowling business.

Despite the relocation of bowling ball production, Brunswick continued to have a significant impact on the Muskegon community. The company's presence in the area for over a century left a lasting legacy, and bowling remained an important part of the local culture.

New Brunswick to Philly: Travel Guide

You may want to see also

The balls are coated in rubber

The rubber coating on Brunswick bowling balls is an important feature that not only ensures the safety of users but also contributes to the durability and performance of the balls. Rubber is a resilient material that can withstand impact and friction, making it ideal for coating bowling balls that are constantly colliding with pins and the lane surface.

In addition to safety and performance benefits, the rubber coating may also provide a tactile advantage for bowlers. The rubber surface can offer a better grip and enhance the bowler's control over the ball, resulting in more precise and accurate throws. This is especially beneficial for competitive bowlers who strive for consistency and precision in their game.

Moreover, the rubber coating on Brunswick bowling balls speaks to the company's history of innovation and market leadership. Brunswick has a long tradition of incorporating new materials and technologies into their products. For instance, they introduced a rubber bowling ball, the Mineralite, in 1906, which revolutionized the game and boosted its popularity.

The use of rubber in Brunswick bowling balls is a testament to the company's commitment to both safety and performance. By coating their balls in rubber, Brunswick ensures that their products are not only durable and high-performing but also safe for users and the environment. This attention to detail and innovation has helped establish Brunswick as a leading brand in the bowling industry.

NYC to Brunswick, Maine: Road Trip

You may want to see also

Frequently asked questions

Brunswick bowling balls are made of rubber and non-hazardous materials.

Yes, Brunswick bowling balls are safe and non-hazardous.

Brunswick bowling balls were historically manufactured in Muskegon, Michigan. However, in the mid-2000s, Brunswick moved its bowling ball production to Reynosa, Mexico, to reduce labor costs.

Brunswick was founded by John Moses Brunswick, a Swiss immigrant who came to America in 1845 and established a carriage-making business in Cincinnati. Over time, Brunswick expanded into billiards and bowling equipment, with Moses Bensinger, Brunswick's son-in-law, playing a pivotal role in the company's entry into the bowling business. Bensinger began making wooden lanes, pins, and bowling balls, and he helped establish the American Bowling Congress in 1895.

In 2021, a man named David Olson discovered 162 Brunswick bowling balls buried beneath his house in Norton Shores, Michigan. This story gained viral attention on Facebook and led to various interviews and a bowling tournament victory for Olson and his wife.