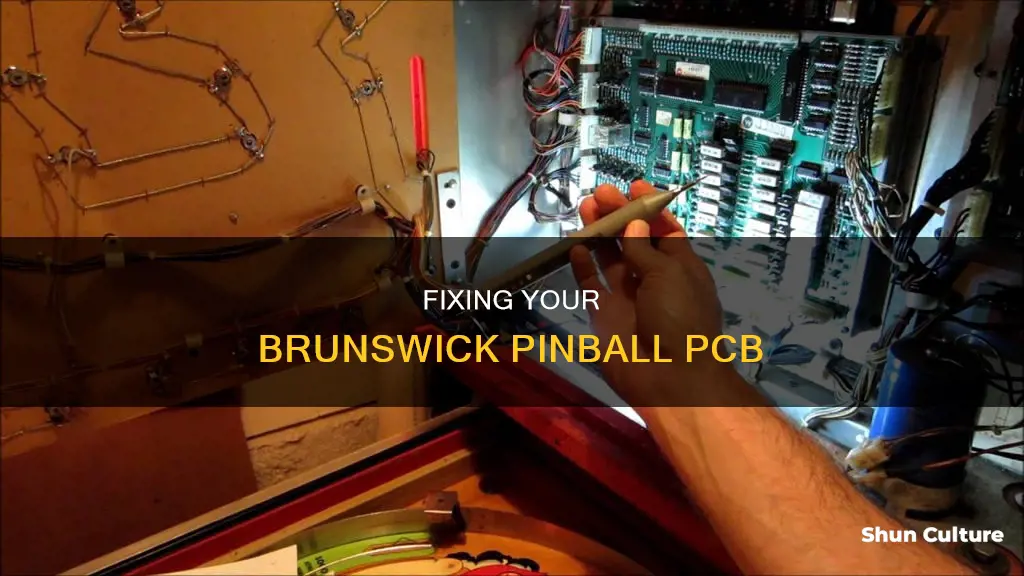

Brunswick pinball machines are a great addition to your home arcade, but they can be a little tricky to fix. The first thing to do is to check the power distribution/rectifier board. This board takes the different AC voltages and converts them to DC, which is what most of the game circuits operate on. Once this board is rebuilt and the output voltage is within the proper operating specifications, you can move on to powering up the other components.

If you're still having issues, the problem could be connector-related. Many problems on these boards stem from the connectors, so you'll need to change out both the male pin on the board and the female in the connector housing.

You'll also want to check for battery corrosion, as this is a common issue with older machines. You'll need to remove any board-mounted battery packs and remotely mount them with a quick disconnect to prevent further damage.

If you're still having issues, you may need to replace the bridge rectifiers, as the original ones tend to be underpowered and fail often.

For more specific issues, you can refer to the schematics and manuals for your particular model, which can be found online.

| Characteristics | Values |

|---|---|

| Problem | Battery corrosion, expired filter capacitors, burnt and/or brittle connectors, bad IC sockets, cold solder points, broken fuse clips, poor ground lines, and required safety modifications |

| Solution | Remote mount a custom-made bridge rectifier board, replace the battery, replace the capacitors, change out connectors, replace IC sockets, re-solder, replace fuse clips, improve ground lines, and make safety modifications |

What You'll Learn

Check for continuity

To check for continuity, you will need a multimeter. This is a device that allows you to test whether a circuit is complete and current can flow through it. Multimeters can be used to test switches, fuses, electrical connections, conductors, and other components.

To set up your multimeter for continuity testing, first select the correct mode. Turn the dial to Continuity Test mode. On some models, you may need to press a continuity button to activate this specific testing mode. Next, connect the test leads. Insert the black test lead into the COM (common) jack, and the red lead into the VΩ jack. Remember to always remove the leads in the reverse order after testing: red first, then black.

With the circuit de-energized, connect the test leads across the component being tested. The position of the test leads is arbitrary, but ensure that the component is isolated from other components in the circuit.

If the circuit is complete and there is a path for current flow, the multimeter will emit a beeping sound. If the circuit is open or incomplete, the multimeter will not beep.

Continuity testing can be used to check simple electrical components like switches, fuses, and wires. For example, a working fuse should show continuity. It can also be used to determine if an exposed electrical conductor is grounded. To do this, place one probe on the conductor and the other on a known electrical ground point.

In the context of repairing a Brunswick pinball machine, continuity testing can help identify any breaks or damage in the circuit board. By testing the continuity of different components and connections, you can locate areas where current is not flowing properly, indicating potential issues that need to be addressed.

It is important to note that power must be disconnected before performing any continuity tests, as these tests require attempting to close an electrical circuit. Additionally, always refer to the specific instructions and guidelines provided by the manufacturer of your multimeter for safe and effective use.

HST Rates in New Brunswick: What's the Deal?

You may want to see also

Check for cold solder joints

Cold solder joints are a common issue with printed circuit boards and can be identified by their rough surface area, rigidity, and generally uneven appearance. They occur when the solder does not melt completely, resulting in a defective joint that is prone to cracking and failing. To check for cold solder joints, follow these steps:

- Visual Inspection: Use a magnifying glass to examine the solder joints. Look for any distortions or deviations from the expected concave shape. Cold solder joints will often appear uneven or distorted.

- Colour Check: A properly dried solder joint should have a dull colour. If the joint appears shiny, it may indicate insufficient heating, which can lead to cold solder joints.

- Light Test: Using a torch and a magnifying glass, check for light leakage through the joints. If light passes through any joints, it indicates improper bonding, and the joint will need to be reworked.

- Board Tilt Test: Tilt the board and check for joints that are partially loosened from the board's base. Also, look for overspills, which can cause short circuits and damage the board.

- Multimeter Test: Use a multimeter to check the resistance and continuity across the solder joints. Set the multimeter to the resistance mode and connect the testing probes to confirm it is working correctly. Then, connect one testing terminal to one joint and the other terminal to a different component. If the value is above zero, it may indicate a cold joint. For continuity testing, put the multimeter in continuity mode. Connect the test terminals and listen for a beep, which confirms continuity. If there is no beep when connecting the terminals across a solder joint, it indicates a problem with the joint.

- Check for Contamination: Contaminants such as grime, grease, and metal oxide can interfere with the soldering process and lead to cold solder joints. Use a clean soldering iron and ensure the work area is free from dirt and debris.

- Check Soldering Technique: Cold solder joints can also result from improper soldering techniques. Ensure that both surfaces are heated sufficiently and that the soldering iron is set at the correct temperature. Take your time during the soldering process and pay close attention to the joints.

- Check Soldering Equipment: Low-quality soldering equipment or equipment that is not functioning properly can contribute to cold solder joints. Invest in good-quality soldering equipment and maintain it regularly to avoid issues.

Brunswick's Beach Count

You may want to see also

Check for burnt or brittle connectors

Burnt or brittle connectors are a common problem in pinball machines, and can be caused by a few different factors. The connectors are often not rated to handle the amount of current that the bulbs draw, which can lead to overheating and burning. This can be exacerbated by the fact that the circuit passes through multiple connectors, and these connectors are often operating at the upper limit of their specifications.

In some cases, the original Molex and pin may be of poor quality, with tin plating that can oxidise and create resistance, generating heat. This can be avoided by using gold-plated pins, though these can be hard to find and expensive.

Another potential cause is that the female spring contact in the connector may crack at the end where it is folded over.

To fix burnt or brittle connectors, you will need to replace the connector and possibly the pins that it plugs into. It is recommended to use Molex Trifurcon 0.156 phosphor bronze crimped connectors as a replacement, as these make a better connection and reduce the chance of overheating. You will also need a crimper, and possibly a de-soldering station if you need to remove the old pins from the circuit board.

It is also a good idea to replace the header pins, especially if they look white/oxidised/black. Get the high-temperature variety if possible, as these are usually black rather than white.

Additionally, switching to LED lights can help reduce the power draw and decrease the chance of connectors burning out.

Lease Breaking: Your NB Rights

You may want to see also

Check for battery corrosion

Battery corrosion is a common issue in pinball machines. It is important to check for it as it can cause serious damage to the circuit board. The first step is to identify whether the battery is leaking. This can be due to several factors such as age, depletion, or external influences like heat and humidity. It is recommended to remove the batteries even if they are not leaking, as they will eventually start to leak.

Once a leaking battery is identified, it is crucial to act fast and neutralize the leakage. The fluid inside the battery is a base, so it needs to be neutralized with an acid such as vinegar. Use a toothbrush and vinegar to neutralize and remove all corrosion, then rinse with distilled water or alcohol to remove any residue. If the damage is severe, you may need to use sandpaper or a small sandblaster to remove the corrosion.

It is important to note that the leakage can spread beyond the battery holder and reach other components and even other boards in the machine. Therefore, it is crucial to inspect the entire machine for any signs of corrosion or damage.

To prevent battery corrosion, one option is to install a memory capacitor instead of batteries. Capacitors will never leak and are suitable for early solid-state pinball machines. Another option is to use a remote battery pack, which keeps the batteries away from the circuit board. However, remote battery packs have some disadvantages, such as the risk of losing memory settings and the possibility of battery leakage.

For Williams WPC games, NVRAM (non-volatile random-access memory) is recommended. NVRAM does not require a battery to retain information. However, for WPC Bally/Williams machines, it is not advisable to install NVRAM unless you are an expert, as the process can damage the fine traces on the circuit board.

Another option is to use watch battery buttons or coin cell batteries, which are lithium batteries known to last up to 5 years and rarely leak. This option requires soldering skills and may involve drilling a tiny hole in the circuit board.

Finally, AA lithium batteries can be used as a replacement for alkaline AA batteries. However, it is important to check the battery holder for any signs of leakage and neutralize it if necessary. A note should be placed with the batteries to remind future users to only use lithium batteries.

Dublin to Brunswick: Miles Count

You may want to see also

Check for expired filter capacitors

Filter capacitors are a common component in pinball machines and they are essential for the proper functioning of the circuit board. However, these capacitors do have a limited shelf life and will eventually expire, which can cause issues with the machine.

The first step is to identify the capacitors on the circuit board. These components typically have two metal leads and are cylindrical or rectangular in shape. They are often labelled with a number that indicates their capacitance value.

To check if the filter capacitors are still functional, you can use a multimeter to measure their capacitance and equivalent series resistance (ESR). Compare the measured values against the original specifications to determine if they are still within acceptable limits.

It is also important to inspect the physical condition of the capacitors. Look for any signs of damage, such as leaking electrolyte, swelling, or bulging at the ends. These visual indicators can suggest that the capacitors are failing or have already expired.

If you suspect that the filter capacitors may be expired, it is recommended to replace them with new ones as a preventive measure. This is especially important if the machine has been stored for a long period without use, as inactivity can accelerate the drying out of the electrolyte.

When replacing the capacitors, ensure that you select the correct type and value for your specific circuit board. Capacitors with similar or higher voltage and capacitance ratings can usually be used as substitutes. However, it is crucial to match the physical dimensions and lead spacing to ensure a proper fit.

Additionally, pay attention to the polarity of the capacitors. Most electrolytic capacitors are polarised, meaning they have a positive and negative lead. The negative lead is usually indicated by a stripe or other marking. Make sure to connect the leads correctly according to the circuit diagram.

By regularly checking and replacing expired filter capacitors, you can help ensure the reliable operation of your Brunswick pinball machine and avoid potential issues caused by failed components.

North Brunswick to Hampton: Travel Time

You may want to see also

Frequently asked questions

If your pinball machine is not responding to the start button, the flippers are not working, and the display is not turning on, your circuit board may be faulty.

If you are confident in your soldering skills, you can attempt to fix the circuit board yourself. You will need a soldering station, solder, a magnifying lamp, a digital multimeter, and a logic probe. If you are not confident in your abilities, it is recommended that you send the circuit board to a professional for repair.

Some common problems with Brunswick pinball machine circuit boards include battery corrosion, expired filter capacitors, burnt or brittle connectors, bad IC sockets, cold solder points, broken fuse clips, and poor ground lines.

You can find parts for your Brunswick pinball machine at The Pinball Resource, Marco Specialties, and Lakeside Pinball Parts.

To prevent battery corrosion from damaging your circuit board, you should remove the batteries from your pinball machine when it is not in use. You can also remote-mount the batteries with a quick disconnect to make it easier to replace them when they start to leak.